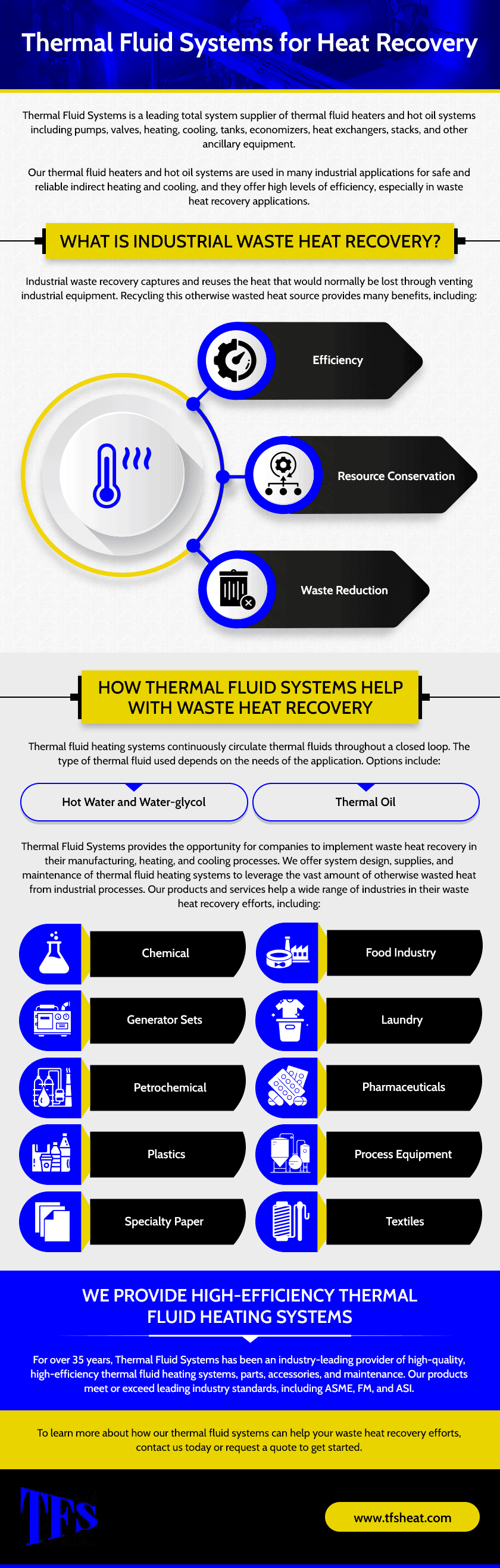

Are you looking for a reliable heated oil system? Thermal Fluid Systems is your most reliable company offering heated oil systems. We specialize in innovative technology that can capture and reclaim previously wasted heat energy, offering high-efficiency systems that are an excellent choice for many industrial applications.

With experience spanning more than 40 years, we have developed a deep understanding of the specifics of their products and can provide cutting-edge advice tailored to your needs. Whether mining coal or processing aluminum, Thermal Fluid Systems has the perfect solution for recovering precious energy sources from production processes with truly amazing results.

Applications of Heated Oil Systems In Different Industries

Chemical

Heated oil systems are used in many applications within the chemical industry. These oil heating systems, sometimes called thermal fluid heaters, provide an efficient and reliable way to transfer heat energy into process fluids. They are designed to operate at high temperatures and pressures, making them suitable for various chemical applications such as process heating, distillation, or drying.

Generator Sets

Heated oil systems for generator sets are designed to ensure that the oil remains heated and in an optimal viscosity range at all times. This allows the engine to operate more efficiently, reducing fuel consumption and emissions. An oil heating system can be used in various applications, from large power plants to standby emergency generators.

Petrochemical

Thermal fluid systems are used extensively in the petrochemical industry. These heat oil systems provide a reliable and efficient means of transferring heat from one point to another, allowing for different temperatures within an industrial process or application. Thermal oil heating systems usually comprise several interconnected components, including a heated oil reservoir, circulating pump, expansion tank, and heat exchanger.

Plastics

These thermal fluid systems provide thermal energy for various processes such as injection molding, thermoforming, and extrusion. The thermal fluid is heated in the thermal oil heater, which is then circulated through pipes to the plastic equipment.

Heated oil systems are a popular way to improve thermal efficiency in plastics applications. They work by recovering heat from the air around an extruder and using it as thermal energy for the plastic-forming process. By reducing thermal losses, thermal fluid systems can help improve performance and lower energy costs.

Specialty Paper

Thermal fluid systems can be used to extract heat from the exhaust of a specialty paper production process, which can then be reused to generate energy or power other processes.

Food Industry

Thermal fluid systems are an essential component of waste heat recovery for the food industry. Thermal fluid heaters are used to convert thermal energy into useful thermal power. These thermal fluid systems transfer thermal energy from a hot source, such as steam from industrial processes or exhaust gases from engines, and convert it into usable thermal power. This thermal power can be used to generate electricity, warm liquids, gases, dry materials, or any other task requiring thermal energy.

Laundry

These heated oil systems transfer heat from one area to another, allowing machine parts to be heated during operation. The heated oil is circulated through pipes and heated with electricity or steam within the unit. This heated oil then passes through a heater exchange coil that warms up any component that needs it, such as water or air.

Pharmaceuticals

Thermal fluid systems are essential in the pharmaceutical industry as they control critical substances’ temperatures, pressures, and flow rates. The systems are composed of pumps, valves, heat exchangers, tanks, and other components that work together to manage a variety of processes throughout the production cycle. These include drug formulation, blending, sterilization, and cleaning.

Process Equipment

Thermal fluid systems play a vital role in the operation of process equipment. They are usually integrated within larger industrial processes, often carrying out heating and cooling tasks on various substances or transferring energy from one source to another. Thermal fluids are used to ensure the efficient operation of machinery at all times.

Textiles

Thermal fluid systems are a key component of textile production. They enable textiles to be heated or cooled, create even temperatures across the entire fabric, and generally speed up the production process.

Thermal fluids typically comprise mineral oils, glycols, synthetic esters, and other organic compounds, enabling heat transfer for various textile processes. The thermal fluid is usually heated before being injected into an exchanger that warms the fabric or yarn on the other side. This allows for precise control over heating levels, so fabrics can be treated with just enough heat to get the desired effect without damaging them in any way.

Thermal fluid systems can be used in batch processes where heated oil is heated up quickly and then cooled rapidly depending on the processing needs. This type of heater is also ideal for continuous production lines that require heated oil over extended periods. The heated oil can be pumped through a series of pipes and valves to different parts of the plant where it’s needed.

How To Choose The Right Heated Oil System for Your Industry

It is crucial to consider the type of heated oil system that best suits your industry. Factors such as the size of the facility, temperature requirements, and safety considerations should all be taken into account when making a decision.

- Facility: The size of your facility will determine what type and size of heating system is appropriate for your needs.

- Temperature Requirements: Different types of heated oil systems have different temperature requirements, so it is crucial to consider the temperature requirements of your specific industry when deciding. Depending on the materials being processed or manufactured, certain temperatures may need to be maintained at all times. For example, producing certain plastics requires heat in the 100-200 degrees Celsius range, while some food processing may need a much lower temperature.

- Safety Considerations: The safety of your staff should always be a priority when choosing a heating system. Heated oil systems can be dangerous if not properly monitored and maintained, so selecting one with sufficient safety features such as automatic shut-offs, pressure relief valves, and low water cutoffs is essential.

Reliable Heated Oil Systems at Thermal Fluid Systems

At Thermal Fluid Systems, Inc., we understand how critical thermal fluid heaters and hot oil systems are to a production feedback loop. That’s why we’re proud to be your supplier of superior thermal product solutions supplier that makes it easy to get the job done right – specializing in delivering innovative solutions designed to maximize performance and safety.

Our line provides the highest quality metal tanks for safe containment and storage of thermal fluids, plus robust heat exchangers allowing swift exchange between controlled and uncontrolled media. In addition, the efficiency of our solutions is further enhanced thanks to our economizers, stacks, and associated equipment, helping you conserve energy while generating maximum returns on your investments.

Whether you seek large or small-scale systems with pumps, valves, heating, cooling, tanks, economizers, heat exchangers, stacks, or any other ancillary equipment – we have it all.

Take advantage of our exceptional products and services today by scheduling a consultation with one of our team members now! Let us help you find the perfect customized solution for your commercial needs. Contact us today to get started with your project.