Hot Oil Heating vs. Steam Request a Quote

Hot oil heating is becoming increasingly popular as an alternative to steam for various industrial applications. Heat transfer oil systems from Thermal Fluid Systems Inc. efficiently and quickly transfer heat from one source to another without pressurizing and can be used in temperatures much higher than those of steam.

Heat transfer oils are also more efficient at providing consistent heat levels across various temperatures, making them ideal for many industrial processes. Let’s discover the difference between hot oil heating vs. steam and why the former has more benefits in your industry.

What is a Hot Oil Heating?

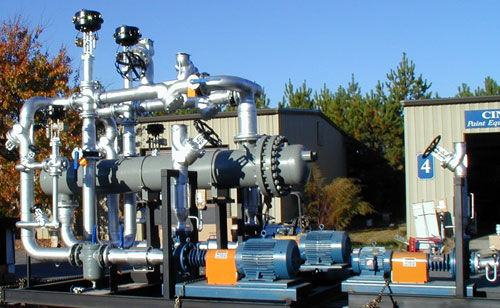

Hot oil heating, also known as thermal fluid heating systems, is an indirect and closed-loop system used to heat fluids for various applications. These systems use special thermal fluid heated in a vessel or tank with an electric or gas-fired burner. The hot oil’s heat is then transferred through piping to radiators, connectors, fan coils, or other heat exchangers.

Heat transfer fluids such as mineral oils, synthetic hydrocarbons, silicones, and esters are used as heat transfer media for hot oil heating systems.

Hot oil heating is used heavily in many industries, including:

- Food and beverage processing

- Chemical production

- Pharmaceutical manufacturing

- Rubber compounding

- Automotive assembly plants.

It can be used for a wide variety of applications, such as:

- Maintaining temperatures for tanks/reactors

- Preheating incoming materials prior to further processing

- Providing reaction temperatures for polymerization processes

- Performing low-pressure maintenance on molds

Between hot oil heating systems vs. steam boilers, hot oil heating is far more efficient as they require lower volumes of energy and don’t create condensation in the process. In addition, they have longer operational lives due to their design which eliminates corrosion problems associated with specific water treatment processes.

Benefits of Hot Oil Heating

Hot oil heating is a cost-effective and reliable form of industrial heating, providing many benefits to industries.

- It does not require a licensed boiler operator: Hot oil heating systems are easy to set up, operate, and maintain. Hot oil does not require a licensed boiler operator or high pressure for operation, making it ideal for industries with limited budget resources.

- Low pressure with high heat: These systems require low pressure for operation but produce high temperatures, making them ideal for heating processes and applications. Hot oil can reach peak operating temperatures more quickly than other heating methods.

- Precise temperature control: Hot oil systems provide precise temperature control, allowing for consistent and predictable heating processes. They can maintain certain temperatures, meaning the system can perform highly complex and delicate heating processes accurately.

- Higher efficiencies: They are designed to maximize efficiency by reducing energy usage without compromising performance. Hot oil operates at higher temperatures than other forms of industrial heating, resulting in improved heat transfer efficiency and reduced fuel costs.

- Unattended system: Hot oil systems can be operated without constant monitoring, reducing labor costs and allowing for more efficient personnel use. Hot oil is also easily integrated into existing industrial systems, which can quickly become an integral part of an industry’s overall system architecture.

Difference Between Hot Oil Heating vs. Steam

Hot oil heating is often considered to be a better option than steam for a variety of reasons.

- Hot oil heating produces higher temperatures than steam systems – allowing for faster production times and greater efficiency applicable to industries requiring heat transfer and process temperatures, such as in the food industry or manufacturing processes requiring high-temperature equipment.

- Hot oil heating also has a higher flash point, meaning it is less likely to cause an explosion when exposed to extreme changes in temperature or pressure.

- They also have a much lower corrosion risk than steam systems, making them ideal for plants dealing with corrosive chemicals or materials.

Choose Thermal Fluid Systems for Your Hot Oil Heating Systems

If you weigh the pros of using hot oil heating vs. steam, hot oil heating systems offer more advantages. This includes lower operating costs, improved safety, and increased control over the temperature.

At Thermal Fluid Systems, Inc., we specialize in providing hot oil heating solutions for various applications. They efficiently offer consistent, reliable heat that can be adjusted quickly and accurately.

If you’re looking for a quality hot oil heating system that meets your needs, contact us or request a quote today! Our experienced team will work with you to design a solution tailored to your application requirements.